-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

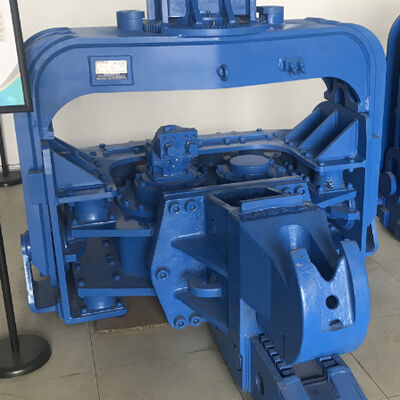

High-Efficiency 3 Ton Vibrating Pile Driver For 15 Meter Large Sheet Piling Construction Projects

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Vibratory Pile Driving Equipment Vibro Hammer | Feature | Easy To Install And Possible To Drive Any Pile |

|---|---|---|---|

| Arm Weight | 750kg | Operation Pressure | 32Mpa |

| Hammer Weight | 2950kg | Vibration Frequency | 3500rpm |

| Centrifugal Force | 470KN | Excavator | 40~45 T |

| Maximum Piling Depth | 15 Meter | Color | Blue/Yellow/Red/White, Customized Color Available |

| HS Code | 8430100000 | Type | Hydraulic Vibrating Hammer |

| Highlight | 3 Ton Vibrating Pile Driver,Vibrating Pile Driver 15 Meter,Construction Sheet Vibratory Hammer Pile Driver |

||

Sheet piles are essential structural components inserted into the ground to retain soil and stabilize water-related construction foundations. Our 3 Ton Vibrating Pile Driver is engineered specifically for 15 meter large sheet piling projects, delivering reliable performance to meet the rigorous demands of foundation engineering.

VIBRA, a seasoned manufacturer with over 12 years of industry experience, provides comprehensive training and on-site installation services for sheet piling operations. Customers can either send their excavators to our yards or our professional team will visit their sites for hands-on guidance. A typical application example is the VIBRA PCF-350 model paired with a Liugong excavator, which is specially designed for driving 15-meter sheet piles efficiently.

- Integrated Imported Control Valve System

Each operational action can be controlled independently, ensuring convenient maintenance and troubleshooting for on-site teams.

- Two-stage Vibration Frequency Control

The second-stage vibration leverages double-pump confluence to significantly boost excitation force, enabling the equipment to overcome complex and special geological conditions.

- Compact & Lightweight Design

The mini and light structure ensures flexible application across various construction sites, with easy transportation and maneuverability.

- Excavator Hydraulic System Compatibility

The pile driver utilizes the excavator’s existing hydraulic system, eliminating the need for additional driving systems and reducing fuel consumption and transportation costs.

- User-friendly Operation

Excavator operators with basic operation experience can master the pile driver with simple practice, minimizing training time and labor costs.

- High-performance Vibration & Excitation Force

Boasts high vibration frequency, strong exciting force, and high structural strength of all components, ensuring efficient piling even in tough soil conditions.

- Superior Durability & Reliability

Equipped with super heavy cast steel fixtures, enlarged oil cylinders, and robust connecting rods, the equipment delivers long-term stable performance with minimal downtime.

- Top-tier Core Components

Adopts Rexroth vibration motors imported from leading European brands, guaranteeing high configuration and consistent operational quality.

The hydraulic vibrating pile driver utilizes high-frequency vibration generated by a hydraulic motor, which is powered by the excavator’s hydraulic system. The vibration force is transmitted to the pile driver to liquefy the surrounding soil and break its structure, reducing friction between the soil and the sheet pile.

The hydraulic motor drives two eccentric shafts to rotate at high speed in opposite directions. The horizontal forces generated by the eccentric shafts cancel each other out, eliminating horizontal vibration, while the vertical forces superimpose to create strong vertical-frequency vibration. This vertical vibration drives or drills the sheet pile into the ground smoothly.

| Item Model | PCF-300 | PCF-330 | PCF-350 | PCF-450 | PCF-500 |

|---|---|---|---|---|---|

| Vibration Frequency (rpm) | 3500 | 3300 | 3500 | 3300 | 3200 |

| Operation Pressure (Mpa) | 32 | 32 | 32 | 32 | 32 |

| Centrifugal Force (kn) | 385 | 420 | 470 | 535 | 585 |

| Max. Pile Length (m) | 12 | 12 | 15 | 18 | 21 |

| Arm Weight (kg) | 750 | 750 | 750 | 820 | 820 |

| Hammer Weight (kg) | 2750 | 2850 | 2950 | 3150 | 3350 |

| Matching Excavator (T) | 27~30 | 33~38 | 40~45 | 47~55 | 55~70 |

-

Q: Are you a manufacturer?

A: Yes. We have over 12 years of experience in the pile driver industry, with our factory located in Suzhou. You are welcome to visit our facility during working hours.

-

Q: Who are your main customers?

A: Our customers are distributed across China and overseas markets including New Zealand, Malaysia, and Indonesia. Renowned brands such as XCMG, SANY, Zoomlion, Cat, and Hyundai are our valued clients.

-

Q: How long is the warranty period?

A: We offer a 12-month warranty for the mainframe and key components, starting from the date of installation completion. Wearable parts are excluded from the warranty.

-

Q: What is the minimum order quantity (MOQ)?

A: The MOQ is 1 set, which is suitable for both small and large-scale construction projects.

-

Q: What payment methods do you accept?

A: We accept T/T .

-

Q: What is the delivery time?

A: The production and delivery time is generally 7–35 days, with goods delivered to Shanghai Port. Additional shipping time is required for overseas destinations.

-

Q: Can we customize the machine with our LOGO?

A: Of course. We provide LOGO customization service to meet your brand promotion needs.

-

Q: How is your product quality guaranteed?

A: Our equipment is manufactured in strict compliance with the technical standards specified in Technical Conditions for Pile Driver Enterprises, ensuring superior quality and performance.

-

Q: Can I become your dealer?

A: We warmly welcome potential dealers. We look forward to developing long-term partnerships, including regional general agent and strategic cooperation opportunities, with ambitious partners.

-

Q: What is the ordering process?

-

Provide us with your required model, quantity, and other customization requirements.

-

We will issue a Proforma Invoice (PI) after confirming the price and details.

-

We arrange production upon receipt of the confirmed PI and your deposit.

-

We will notify you of the shipment date and related information via email once the goods are ready for delivery.

-

We will track the goods until you receive them safely.

-