-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

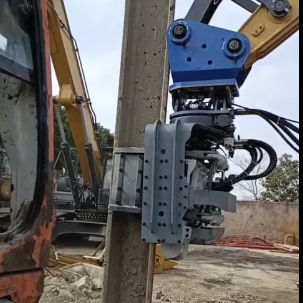

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

Side Grip Vibratory Pile Hammer: Excavator Mounted & 360° Rotation

| Name | Side Grip Pile Driver | Feature | Pile Driving In Small Working Areas |

|---|---|---|---|

| Vibration | 3000 Rpm | Centrifugal Force | 332-384 KN |

| Hammer | 1400-1700 Kg | Excavator | 20T |

| Material | Steel, Core Materials Are All Imported | Color | Blue, Customized Color Available |

| HS Code | 84301000 | Size (LxWxH) | 1320X1160X1820 |

| Rotation/tilt Angle | 360/+-30 Degree | Eccentric Torque | 3.07kgm |

| Highlight | Side Grip Vibratory Pile Driver,Excavator Mounted Sheet Vibro Hammer,Excavator Mounted Vibratory Pile Driver |

||

The VIBRA Side Grip Vibratory Pile Driver is a high-performance, excavator-mounted construction equipment designed for safe, efficient pile driving and extraction. Engineered with side and base clamping systems, it outperforms conventional pile drivers in speed and precision, enabling seamless pile handling, tilting, and rotation without manual intervention or auxiliary machinery. Hydraulically powered by the excavator and operated by the excavator operator, this pile driver features an ergonomic design, low-noise operation, and versatile adaptability to diverse piles, ground conditions, and construction projects.

Pile Driver, Side Grip Pile Driver, Excavator-Mounted Pile Driver, Vibratory Pile Driver, Hydraulic Pile Driver, Sheet Pile Driver, Low-Noise Pile Driver, Multi-Purpose Pile Driver

- Dual Clamping System: Equipped with side and bottom clips (one-piece cast steel bottom clip with integrated cylinder and tooth plate) for secure pile gripping, synchronized clamping/release, and protection against pile damage.

- Excavator Compatibility: Easily mounted to any brand of excavator via a VIBRA-designed connection bracket, hydraulically driven by the excavator for seamless integration and operation.

- 360° Rotation & Tilt Function: Features a high-torque slewing support and high-pressure swing cylinder, enabling 360° rotation and ±30° tilting for precise pile positioning.

- Low-Noise Operation: Fitted with a rubber sheath to reduce noise, ensuring quiet operation that complies with environmental requirements, even in urban or building-adjacent areas.

- Ergonomic & User-Friendly Design: Intuitive operation by the excavator operator, with a compact structure, light-weight hydraulic motor (high power/speed output), and hassle-free maintenance.

- Adjustable Vibration Frequency: Vibration frequency is adjustable via a variable pump, allowing customization to meet different ground conditions and pile types.

- Enhanced Safety & Precision: Eliminates manual pile handling and auxiliary machinery, reducing operational risks; dual clamping and precise rotation/tilting ensure accurate pile placement.

- Superior Efficiency: Faster pile driving/extraction cycles, shorter working periods, and quick operation conversion, significantly saving time and costs.

- Wide Versatility: Adapts to various pile types (sheet piles, casing piles, H/I-beams, steel tube piles, cement piles, rail piles) and diverse ground conditions, suitable for multiple construction projects.

- Durability & Reliability: Built with high-strength components (one-piece gantry hanger, high-strength box vibrating body, imported drive motor), ensuring long service life and trouble-free operation.

- Gentle Pile & Structure Protection: Prevents damage to pile tops/bottoms and nearby buildings, even during close-proximity operations.

- Easy Maintenance: Simplified design with accessible components, reducing maintenance efforts and downtime.

| Design Component | Key Features |

|---|---|

| Rotary Oscillation Mechanism | High torque slewing support, high-pressure swing cylinder, split control valve, compact central swivel |

| Gantry Hanger | One-piece structure, high-pressure accumulator, front oil circuit interface |

| Holding Clip System | High-strength arms, dual high-pressure cylinders, interchangeable collet, synchronized clamping/release |

| Vibrating Body | Imported drive motor, high-strength box, high-speed gear, symmetrical eccentric arrangement |

| Bottom Clip System | One-piece cast steel, integrated cylinder, tooth plate, pile hook mechanism |

A1: 12 months from the date of installation completion, covering the mainframe and key components (excluding wearing parts).

A2: 1 set is acceptable, supporting flexible procurement for projects of all scales.

A3: We support T/T (Telegraphic Transfer) and D/P (Documents against Payment) for convenient global transactions.

A4: The standard delivery time is 7-35 days, with goods delivered to Shanghai Port. Overseas customers need to consider additional shipping time.

A5: Yes, logo customization is available to meet your branding and marketing needs.

A6: Our equipment is strictly manufactured in accordance with the "Technical Conditions for Pile Driver Enterprises" industry standards, ensuring consistent and reliable quality.

A7: We warmly welcome dealer partnerships and look forward to developing long-term regional general agent and strategic cooperative relationships with ambitious partners worldwide.