-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

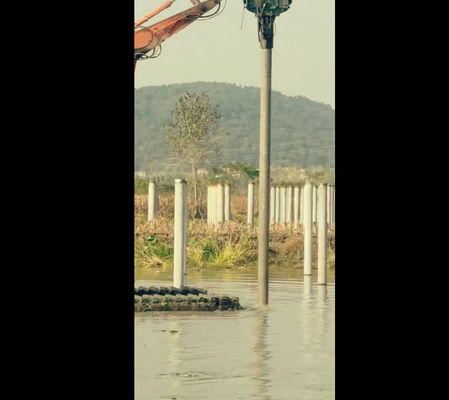

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

Pile Driver - Sustainable Solution for Mini Sheet Piles

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Small Pile Driving Equipment | Feature | Green Color |

|---|---|---|---|

| Vibration Frequency | 2500 Rpm | Operation Pressure | 30 Mpa |

| Centrifugal Force | 117 KN | Max.Pile Length | 6 M |

| Arm Weight | 160 Kg | Hammer Weight | 850 Kg |

| Material | Steel, Core Materials Are All Imported | Color | Blue/Yellow, Customized Color Available |

| Type | New And Used Both Available | HS Code | 84301000 |

| Highlight | Environment Friendly Sheet Pile Driver,6m Sheet Pile Driver,30Mpa excavator sheet pile driver |

||

Product Name: Pile Driver - Sustainable Solution for Mini Sheet Piles

Core Keywords: pile driver, hydraulic pile driver, eco-friendly pile driver, vibrating pile hammer, excavator mounted pile driver, silent pile driver

Product Overview

The VIBRA Eco-Friendly Hydraulic Pile Driver represents a breakthrough in sustainable construction equipment. Combining advanced high-frequency vibration technology with innovative noise-reduction systems, this machine delivers exceptional performance while minimizing environmental impact. Ideal for urban construction projects and environmentally sensitive areas, it sets new standards for eco-conscious pile driving operations.

Key Features

- Advanced rubber sheath noise reduction technology

- High-frequency vibration system (2500 RPM)

- Multi-functional compatibility for various pile types

- Compact hydraulic motor with high power output

- Variable frequency adjustment capability

- Universal excavator compatibility

- Quick-chuck change system

Product Advantages

- Environmental Protection: Specialized rubber sheath reduces noise pollution by up to 70%

- Versatile Application: Handles steel sheet piles, cement piles, H-beams, and rail piles

- Operational Efficiency: 30% faster setup time compared to conventional systems

- Reduced Extraction Force: Requires 40% less force for pile pulling operations

- Pile Protection: Prevents damage to pile tops and bottoms during operation

- Site Safety: Safe operation within 1 meter of existing structures

- Compact Design: High power-to-weight ratio for easy transportation

- Adaptive Performance: Adjustable settings for different soil conditions

Technical Specifications

| Parameter | FV-100 | FV-150 |

|---|---|---|

| Vibration Frequency | 2500 rpm | 2500 rpm |

| Operating Pressure | 30 MPa | 30 MPa |

| Centrifugal Force | 117 kN | 172 kN |

| Max Pile Length | 6 m | 8 m |

| Arm Weight | 160 kg | 260 kg |

| Hammer Weight | 850 kg | 1100 kg |

| Suitable Excavator | 7-12 T | 12-17 T |

Working Principle

The VIBRA system utilizes high-frequency vibration to transfer mechanical energy to the pile body, causing soil liquefaction around the pile. This process reduces friction between the pile and soil by up to 60%, enabling smooth penetration using the combined force of excavator pressure and pile weight. The system automatically adjusts excitation power based on real-time soil conditions and pile specifications.

Frequently Asked Questions

Q: How effective is the noise reduction technology?

A: Our rubber sheath system reduces operational noise by 65-70%, making it suitable for residential areas and noise-sensitive environments like hospitals and schools.

Q: What is the maximum working distance from existing structures?

A: The equipment can safely operate within 1 meter of existing buildings without risking structural damage, thanks to precision vibration control.

Q: What is your warranty and delivery terms?

A: We offer 12-month warranty on main components with delivery within 1-8 days to Shanghai port. MOQ is one set with L/C, T/T, and D/P payment options.

Q: Can the equipment handle different soil conditions?

A: Yes, the adjustable frequency system adapts to various soil types including clay, sand, and mixed soils, with automatic power calibration.

Q: How quickly can chuck changes be performed?

A: The quick-chuck system allows for tool changes in under 5 minutes, significantly reducing downtime between different pile types.

Why Choose VIBRA

- Industry-leading noise reduction technology

- Proven performance in over 500 projects worldwide

- ISO 9001 certified manufacturing processes

- Continuous R&D investment for product improvement

- 24/7 technical support and service network

- Environmentally certified operations

Quality Assurance

All VIBRA equipment undergoes rigorous testing and complies with international standards including CE certification and "Technical Conditions for Pile Driver Enterprises" specifications. Each unit includes comprehensive documentation and operational guidelines.