-

Hydraulic Pile Driver

-

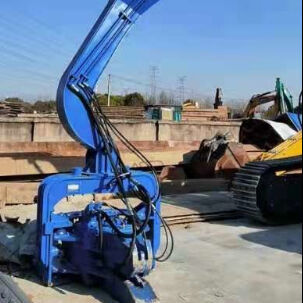

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

Industrial Pile Driver for Solar Farms: 32Mpa Hydraulic System & Universal Crane Compatibility

| Name | Sheet Pile Driving Machine | Main Feature | Short Working Period |

|---|---|---|---|

| Frequency | 3200rpm | Pressure | 32Mpa |

| Arm Weight | 670kg | Hammer Weight | 2400kg |

| Centrifugal Force | 435KN | Excavator Operating Weight | 35-40T |

| Highlight | 32Mpa sheet pile hammer,sheet crane vibro hammer,32Mpa hydraulic vibratory hammer |

||

VIBRA Universal Hydraulic Pile Driver: Quiet, Powerful, and Unmatched in Compatibility

Core Product Keywords: Hydraulic Vibratory Pile Driver, VIBRA Pile Driver, Universal Pile Driver, Excavator-Mounted Pile Hammer, Low-Noise Pile Driver, Multi-Purpose Pile Driver.

Product Overview

The VIBRA Series Hydraulic Pile Driver sets the industry standard for versatility and performance. Engineered for universal compatibility, it seamlessly integrates with any excavator from 6 to 60 tons and is trusted by leading global excavator brands. Designed to drive and extract all common pile types, it combines formidable power with environmentally conscious, quiet operation for projects in any setting.

Key Features & Technological Advantages

Unrivaled Universal Compatibility: Certified and adopted by major excavator manufacturers. Fits any brand and model of excavator within the 6-60 ton operating weight range, maximizing your fleet's utility and flexibility.

Eco-Friendly, Low-Noise Operation: Fitted with a specialized rubber sheath that dramatically reduces noise and vibration. Enables quiet, extended work periods in noise-sensitive urban or residential environments, helping projects meet strict regulations.

Superior Pile Protection & Efficiency: Patented clamping technology protects the top and bottom of steel pipe, sheet, and rail piles from damage during driving and extraction. Requires significantly less force for pile pulling compared to other systems, saving time and energy.

High-Power, Compact Design: Features a hydraulic motor that delivers high power and speed from a small, lightweight package. The adjustable vibration frequency via a variable pump allows precise optimization for different soils and pile types.

Safe for Proximity Work: Engineered to operate safely near existing structures without causing damage to foundations or buildings, ideal for tight urban job sites and retrofit projects.

Technical Parameters: VIBRA Universal Series

| Model | Frequency (RPM) | Centrifugal Force (KN) | Max. Pile Length (m) | Recommended Excavator (T) | Total Weight (kg) |

|---|---|---|---|---|---|

| FV-280 | 2800 | 335 | 12 | 20-30 | 2400 |

| FV-300 | 3200 | 350 | 12 | 30-35 | 2770 |

| FV-350S | 3200 | 435 | 15 | 35-40 | 3070 |

| FV-350 | 3200 | 455 | 15 | 40-45 | 3350 |

| FV-400 | 3200 | 485 | 18 | 45-60 | 3450 |

Primary Applications

Ideal for a vast range of piling tasks including steel sheet piles, concrete piles, H-beams, and pipe piles. Widely used in infrastructure projects like waterway embankments, building foundations, municipal works, bridge construction, and urban redevelopment.

Frequently Asked Questions (FAQ)

Q: Is the VIBRA pile driver really compatible with any excavator brand?

A: Yes. Our mounting system is universally designed and has been adopted by almost all renowned excavator brands. It can be fitted to any excavator with an operating weight between 6 and 60 tons.

Q: How effective is the noise reduction feature?

A: The integrated rubber sheath significantly dampens operational noise and vibration, making it one of the quietest pile drivers on the market. This is crucial for projects with noise restrictions or in populated areas.

Q: How does it protect piles from damage?

A: Our specially engineered clamps distribute pressure evenly across the pile head, preventing the crushing, deformation, or "mushrooming" that commonly occurs with standard pile drivers, thereby preserving material integrity and value.

Q: Can it be used for both driving and extracting piles?

A: Absolutely. It is highly efficient for both operations. Its design is so effective that it requires less hydraulic force for extraction compared to other systems, reducing strain on the carrier machine.

Q: What is the advantage of the adjustable vibration frequency?

A: The variable pump allows operators to fine-tune the vibration frequency to match specific ground conditions and pile types. This optimizes driving speed, improves efficiency, and prevents pile damage.

About YEKUN

Founded in 2009, Shanghai Yekun Construction Machinery Co., Ltd. is a professional and visionary enterprise dedicated to the innovation, manufacture, and service of high-speed hydraulic vibratory pile drivers. Our commitment to quality, powered by the latest technology and guided by expert consultants, has made our VIBRA series a globally recognized leader. We collaborate closely with construction teams and machinery factories to develop practical solutions, driven by a young, passionate team committed to putting the client first and becoming the most comprehensive supplier in the industry.