-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

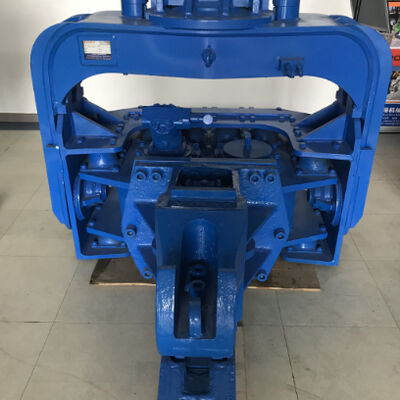

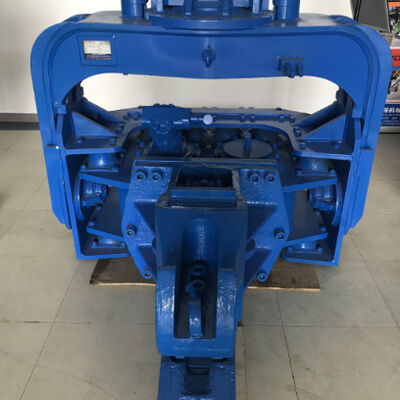

Excavator Mounted Pile Driver - Low Noise Hydraulic & Multi-Pile Type Adaptation

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Excavator Mounted Pile Driver | Arm Weight | 670kg |

|---|---|---|---|

| Hammer Weight | 2400kg | Operation Pressure | 32Mpa |

| Vibration Frequency | 3200 Rpm | Max.Pile Length | 15m |

| Centrifugal Force | 435kn | Excavator | 35~40 Ton |

| Highlight | excavator mounted sheet pile driver,excavator mounted wood pile driver |

||

Pile Driver, Low Noise Pile Driver, Hydraulic Pile Driver, Excavator Mounted Pile Driver, All-Terrain Pile Driver, Multi-Pile Type Pile Driver, High Power Pile Driver, Quiet Operation Pile Driver

Shanghai Yekun Machinery Co., Ltd., founded in 2014, is a professional enterprise specializing in the manufacture, sale and service of hydraulic vibrating pile drivers. Our flagship product, the Low Noise Hydraulic Excavator Mounted Pile Driver, boasts exceptional adaptability to all terrains and complex working conditions, delivering reliable and efficient piling solutions for infrastructure and construction industries worldwide.

Engineered with advanced hydraulic technology and rubber sheath noise reduction, this pile driver achieves quiet operation while maintaining high power output—its compact, lightweight hydraulic motor ensures strong performance without compromising environmental friendliness. Backed by a young and enthusiastic professional team, we adhere to “Client as Priority, Quality as First Concern, Management as Foundation” and collaborate with engineering machinery factories and foreign technical advisers to drive product innovation. Our mini, medium and large hydraulic vibrating pile drivers lead industry trends and are highly recognized by clients globally.

- All-Terrain Adaptability: Excels in various terrains and complex working conditions, suitable for onshore, marshland, river-bank and other challenging construction scenarios.

- Low Noise & Quiet Operation: Equipped with rubber sheaths to reduce noise and vibration, meeting environmental standards and ideal for construction near buildings or residential areas.

- Advanced Hydraulic Technology: High-performance hydraulic motor and two-level double pumps enhance excitation force, enabling efficient piling and pile pulling with minimal energy consumption.

- Multi-Pile Type Compatibility: Capable of driving steel sheet piles, cement piles, steel rail piles, iron plates and H steel, fully satisfying diverse foundation engineering requirements.

- Flexible & Efficient Operation: Features quick converting operation and requires less force for pile pulling compared to other systems, improving construction efficiency and reducing labor intensity.

- Precise Adjustment Capabilities: Supports 180° forward/reverse rotation for sheet pile clamping and lowering; vibration frequency adjustable via variable pump to adapt to different site conditions.

- Universal Excavator Compatibility: Works with any brand of excavator; only needs to change chucks to meet different construction needs, eliminating equipment matching limitations.

- Protective & Safe Design: Does not damage the top or bottom of steel pipe piles, steel sheet piles and steel rail piles; safe for operation near buildings without structural harm.

- Short Working Period: High-power output and optimized operation logic shorten construction cycles, helping clients meet project deadlines efficiently.

- Triple Core Advantages: Integrates low noise, hydraulic power and all-terrain adaptability, ensuring stable performance in diverse environments while minimizing environmental impact.

- Strong Technical Strength: Collaboration with engineering machinery factories and foreign technical advisers ensures product technology is at the industry forefront, with reliable quality and durability.

- Cost-Effective Operation: Universal compatibility reduces equipment investment; efficient operation and low maintenance needs lower long-term project costs.

- Comprehensive Adaptability: Multi-pile type support and all-terrain performance expand application scope, suitable for infrastructure, municipal, bridge and road construction projects.

- User-Centered Service: Young professional team provides pre-sales consultation and after-sales support; flexible customization (LOGO) and payment terms meet diverse customer needs.

- Proven Quality Assurance: Strictly produced in accordance with Technical Conditions for Pile Driver Enterprises, with products undergoing rigorous testing to ensure consistent performance.

| Item | FV-250 | FV-280 | FV-300 | FV-330 | FV-350S | FV-350 | FV-400 |

|---|---|---|---|---|---|---|---|

| Vibration Frequency (rpm) | 2500 | 2800 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Operation Pressure (Mpa) | 30 | 32 | 32 | 32 | 32 | 32 | 32 |

| Centrifugal Force (KN) | 265 | 335 | 350 | 372 | 435 | 455 | 485 |

| Max. Pile Length (m) | 10 | 12 | 12 | 12 | 15 | 15 | 18 |

| Arm Weight (kg) | 1700 | 1900 | 2100 | 2300 | 2400 | 2600 | 2700 |

| Matching Excavator (T) | 20-30 | 20-30 | 30-35 | 33-40 | 35-40 | 40-45 | 45-60 |

Q: What is the warranty period for the pile driver?

A: The warranty period is 12 months from the date of completion of installation, covering the mainframe and key components, excluding wearing parts.

Q: What is the minimum order quantity (MOQ) for this pile driver?

A: The MOQ is one set, which is flexible enough to meet the needs of trial purchases and large-scale bulk orders.

Q: Which payment methods do you accept for pile driver orders?

A: We accept T/T (Telegraphic Transfer).

Q: What is the delivery time for the pile driver?

A: The production delivery time is generally 1–8 days, and the products will be delivered to Shanghai Port. For overseas orders, please take the additional international shipping time to your destination into consideration.

Q: Can I customize my own LOGO on the pile driver?

A: Of course you can. We provide LOGO customization service to help you promote your brand on the equipment.

Q: How do you ensure the quality of your pile driver products?

A: All our equipment is strictly produced and inspected in full compliance with the technical standards specified in the Technical Conditions for Pile Driver Enterprises. We also leverage the latest industrial technology for quality control and product optimization.

Q: Can I apply to be a dealer of your pile driver products?

A: We warmly welcome you to become our dealer. We are also looking forward to further developing into regional general agents and strategic partners with ambitious partners like you.