-

Hydraulic Pile Driver

-

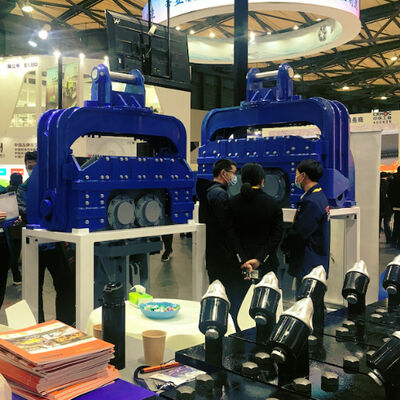

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

High-Efficiency Excavator Mounted Vibro Hammer Pile Driver – 2800rpm For 10 Meter Piling Work

| Name | Excavator Mounted Pile Driver::Piling And Pulling | Color | Blue/Yellow/Red/White, Customized Color Available |

|---|---|---|---|

| Vibration Frequency | 2800rpm | Operation Pressure | 32Mpa |

| Hammer Weight | 1700kg | Arm Weight | 5000kg |

| Max.Pile Length | 10m | Centrifugal Force | 265Kn |

| Excavator | 20-30 Ton | Hanging Amplitude | 6mm |

| Eccentric Moment | 2.5kgm | HS Code | 8430100000 As Pile Driver Accessories |

| Highlight | Construction Excavator Mounted Vibro Hammer,10 Meter Vibratory Pile Driver,Excavator Mounted Pile Driver 2800rpm |

||

Pile Driver, Vibro Hammer Pile Driver, Hydraulic Vibrating Pile Driver, Excavator Mounted Pile Driver, 10 Meter Piling Equipment, Foundation Construction Pile Driver

VIBRA offers a comprehensive range of hydraulic vibrating pile drivers/vibro hammers designed for excavator mounting, catering to piling construction needs with pile lengths up to 24 meters, including the targeted 10-meter piling scenarios. In the market, vibratory hammers are mainly categorized into electric and hydraulic types; both share basic structural traits like dedicated power units, pile-clamping mechanisms, and connection cables/hoses, while VIBRA’s hydraulic models stand out for superior adaptability.

Our equipment is compatible with 6–60 ton excavators of almost all leading global brands, including Caterpillar, Volvo, Hyundai, Hitachi, XCMG, SANY, and Zoomlion. This broad compatibility ensures that customers can integrate our pile drivers with their existing machinery seamlessly, meeting diverse foundation construction requirements.

- Independent Action Control System: Adopts imported integrated control valves, enabling separate and precise control of each operational action. This design simplifies maintenance and inspection procedures, reducing downtime.

- Dual-Stage Vibration Frequency Adjustment: Features two-level vibration control, with the second stage utilizing double-pump confluence. This significantly boosts excitation force, allowing the equipment to overcome complex and special geological conditions.

- Compact & Lightweight Design: The miniaturized and lightweight structure ensures flexible application, especially suitable for narrow construction sites or projects with space constraints.

- Excavator Hydraulic System Compatibility: Leverages the excavator’s own hydraulic system for power, eliminating the need for an additional independent driving system.

- User-Friendly Operation: Simple to learn and operate; operators with basic excavator operation experience can master the equipment after a short period of practice.

- Broad Compatibility: Fits 6–60 ton excavators from mainstream global brands, eliminating the need for customers to purchase new host equipment and reducing investment costs.

- Strong Geological Adaptability: The dual-stage vibration frequency adjustment and high excitation force enable efficient piling in various complex soil conditions, ensuring stable construction progress.

- Cost-Effective Performance: Utilizing the excavator’s hydraulic system cuts fuel consumption and transportation costs. The compact design also lowers storage and handling expenses.

- Extended Piling Range: While optimized for 10-meter piling tasks, the equipment can handle pile lengths up to 24 meters, meeting the needs of different construction projects.

- Reliable Quality & After-Sales Support: Backed by strict manufacturing standards and a professional service team, ensuring long-term stable operation and timely after-sales assistance.

| Item | FV-250 | FV-280 | FV-300 | FV-330 | FV-350S | FV-350 | FV-400 |

|---|---|---|---|---|---|---|---|

| Vibration Frequency (rpm) | 2800 | 2800 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Operation Pressure (Mpa) | 30 | 32 | 32 | 32 | 32 | 32 | 32 |

| Centrifugal Force (KN) | 265 | 335 | 350 | 372 | 435 | 455 | 485 |

| Max. Pile Length (m) | 10 | 12 | 12 | 12 | 15 | 15 | 18 |

| Arm Weight (kg) | 500 | 500 | 670 | 670 | 670 | 750 | 750 |

| Hammer Weight (kg) | 1700 | 1900 | 2100 | 2300 | 2400 | 2600 | 2700 |

| Matching Excavator (T) | 20–30 | 20–30 | 30–35 | 33–40 | 35–40 | 40–45 | 45–60 |

The hydraulic vibrating pile driver harnesses high-frequency vibration generated by a hydraulic motor, which is powered by the excavator’s hydraulic system. The motor drives two eccentric shafts to rotate at high speed in opposite directions. The horizontal vibration forces produced by the eccentric shafts cancel each other out, while the vertical forces superimpose to form strong vertical-frequency vibrations.

These vertical vibrations are transferred to the pile, liquefying the surrounding soil and breaking its structure to reduce friction between the pile and the soil. This allows the excavator to smoothly drive or drill the pile into the ground, completing piling tasks efficiently.

Q: Are you a manufacturer?

A: Yes, we have over 12 years of experience in the pile driver industry. Our factory is located in Suzhou, and you are welcome to visit our facility during working hours.

Q: Who is your main customer?

A: Our customers are distributed across China and in overseas markets including New Zealand, Malaysia, and Indonesia. Renowned brands such as XCMG, SANY, Zoomlion, Caterpillar, and Hyundai are our valued clients.

Q: How long is the warranty period?

A: The mainframe and key components come with a 12-month warranty from the date of installation completion, excluding wearing parts.

Q: What is the MOQ?

A: The minimum order quantity is 1 set.

Q: What payment methods do you accept?

A: We accept T/T.

Q: What is the delivery time?

A: The general delivery time is 7–35 days, with delivery to Shanghai Port. Additional shipping time should be considered for overseas destinations.

Q: Can I customize the machine with our logo?

A: Of course, we offer logo customization services to meet your brand promotion needs.

Q: How is your product quality guaranteed?

A: Our equipment is manufactured strictly in accordance with the technical standards specified in the Technical Conditions for Pile Driver Enterprises.

Q: Can I become your dealer?

A: We warmly welcome you to become our dealer. We also look forward to developing long-term partnerships with ambitious individuals to become regional general agents and strategic partners.