-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

XCMG Heavy-Duty Vibrating Pile Driver – High-Efficiency Solution For Sheet Piling Works

| Name | Photovoltaic Series Pile Driver | Feature | Accurate |

|---|---|---|---|

| Arm Weight | 500kg | Operation Pressure | 32Mpa |

| Hammer Weight | 1700kg | Vibration Frequency | 2800rpm |

| Centrifugal Force | 265KN | Excavator | 20-30T |

| Piling Depth | 10 Meter | Material | Steel, Core Materials Are All Imported |

| HS Code | 8430100000 | Color | Blue/Yellow/Red/White, Customized Color Available |

| Highlight | XCMG Vibrating Pile Driver,Sheet Piling Vibrating Pile Driver,Construction Vibratory Hammer Pile Driver |

||

Core Keywords: XCMG Vibrating Pile Driver, Hydraulic Pile Driver, Sheet Piling Construction Equipment, High-Frequency Pile Driver

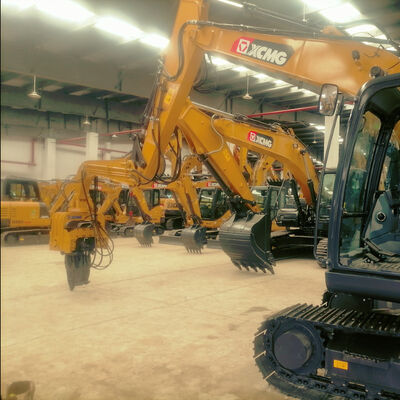

Shanghai Yekun Construction Machinery Co., Ltd. (Brand: VIBRA) is delighted to announce the signing of a Memorandum of Understanding (MoU) with XCMG Group – a renowned Chinese multinational state-owned heavy machinery manufacturer. XCMG holds the record as the world’s fastest enterprise to achieve 200,000 units of excavator production and sales, reshaping the global industrial competition landscape with "Made in China" strength.

Under this partnership, VIBRA will produce XCMG-branded vibrating pile drivers to serve global customers. We extend our sincere congratulations to XCMG on this remarkable milestone and look forward to a long-term, mutually beneficial cooperation.

The hydraulic vibrating pile driver leverages high-frequency vibration generated by a hydraulic motor (powered by the matching excavator’s hydraulic system). This vibration force is transmitted to the pile driver, liquefying the surrounding soil and breaking its structure to minimize friction between the soil and the sheet pile.

The hydraulic motor drives two eccentric shafts to rotate at high speed in opposite directions. The horizontal forces generated by the eccentric shafts cancel each other out, eliminating horizontal vibration, while the vertical forces superimpose to create strong vertical-frequency vibration. This targeted vertical vibration enables smooth piling or drilling of sheet piles into the ground.

-

Integrated Imported Control Valve System

The control system adopts top-tier imported integrated valves, allowing independent control of each operational action. This design ensures convenient maintenance and troubleshooting for on-site teams.

-

Two-stage Vibration Frequency Control

The pile driver features dual-stage vibration frequency regulation. The second stage utilizes double-pump confluence, which significantly boosts excitation force and enables the equipment to tackle complex and special geological conditions with ease.

-

Compact & Lightweight Design

With a mini and lightweight structure, the pile driver offers flexible application across diverse construction sites, reducing transportation hassle and improving maneuverability in narrow working spaces.

-

Excavator Hydraulic System Compatibility

The equipment directly utilizes the excavator’s existing hydraulic system, eliminating the need for additional independent driving systems. This not only saves fuel costs but also cuts down on transportation and installation expenses.

-

User-friendly Operation

The operation process is simple and easy to master. Operators with basic excavator operation experience can proficiently operate the pile driver after short-term practical training, minimizing labor training costs.

-

Powerful Vibration Moment & Compact Structure

Boasts strong vibration moment for efficient soil penetration, paired with a compact, lightweight design that ensures high flexibility in various sheet piling scenarios.

-

High-Configuration Core Components

The entire machine is equipped with premium components, including high-performance hydraulic motors, German FAG bearings, and other key parts imported from world-renowned brands, guaranteeing stable and durable performance.

| Item | FV-250 | FV-280 | FV-300 | FV-330 | FV-350S | FV-350 | FV-400 |

|---|---|---|---|---|---|---|---|

| Vibration Frequency (rpm) | 2800 | 2800 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Operation Pressure (Mpa) | 30 | 32 | 32 | 32 | 32 | 32 | 32 |

| Centrifugal Force (KN) | 265 | 335 | 350 | 372 | 435 | 455 | 485 |

| Max. Pile Length (m) | 10 | 12 | 12 | 12 | 15 | 15 | 18 |

| Arm Weight (kg) | 500 | 500 | 670 | 670 | 670 | 750 | 750 |

| Hammer Weight (kg) | 1700 | 1900 | 2100 | 2300 | 2400 | 2600 | 2700 |

| Matching Excavator (T) | 20-30 | 20-30 | 30-35 | 33-40 | 35-40 | 40-45 | 45-60 |

Founded in 2014, Shanghai Yekun Machinery Co., Ltd. is a professional manufacturer, seller, and service provider specializing in hydraulic vibrating pile drivers. Our core products include state-of-the-art high-speed hydraulic vibrating pile drivers and their components, widely applied in global infrastructure and construction industries.

We prioritize product quality and adopt cutting-edge industrial technologies. Our mini hydraulic vibrating pile drivers lead the industry trend, while our medium and large-sized models are highly recognized by domestic and international clients. We actively cooperate with engineering machinery factories and construction companies to develop more functional professional equipment, and we have hired foreign technical experts to provide professional guidance.

Our company boasts a young, passionate, and professional team. Adhering to the principles of customer priority, quality first, and management foundation, we are committed to becoming the world’s most professional and comprehensive hydraulic vibrating pile driver manufacturer and service supplier.

-

Q: Are you a manufacturer?A: Yes. We have over 12 years of experience in the pile driver industry, with our factory located in Suzhou. You are welcome to visit our facility during working hours.

-

Q: Who are your main customers?A: Our customers are distributed across China and overseas markets including New Zealand, Malaysia, and Indonesia. Renowned brands such as XCMG, SANY, Zoomlion, Cat, and Hyundai are our valued clients.

-

Q: How long is the warranty period?A: We offer a 12-month warranty for the mainframe and key components, starting from the date of installation completion. Wearable parts are excluded from the warranty.

-

Q: What is the minimum order quantity (MOQ)?A: The MOQ is 1 set, suitable for both small and large-scale construction projects.

-

Q: What payment methods do you accept?A: We accept T/T for global customers.

-

Q: What is the delivery time?A: The production and delivery time is generally 7–35 days, with goods delivered to Shanghai Port. Additional shipping time is required for overseas destinations.

-

Q: Can we customize the machine with our LOGO?A: Of course. We provide LOGO customization service to meet your brand promotion needs.

-

Q: How is your product quality guaranteed?A: Our equipment is manufactured in strict compliance with the technical standards specified in Technical Conditions for Pile Driver Enterprises, ensuring superior quality and stable performance.

-

Q: Can I become your dealer?A: We warmly welcome potential dealers. We look forward to developing long-term partnerships, including regional general agent and strategic cooperation opportunities, with ambitious partners.

-

Q: What is the ordering process?

-

Provide us with your required model, quantity, and other customization requirements.

-

We will issue a Proforma Invoice (PI) after confirming the price and details.

-

We arrange production upon receipt of the confirmed PI and your deposit .

-

We will notify you of the shipment date and related information via email once the goods are ready for delivery.

-

We will track the goods until you receive them safely.

-