-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

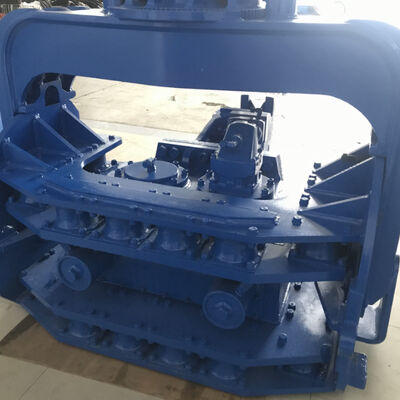

High-Performance Pile Driver for CAT E450: 18m Depth & 3200rpm Vibro Hammer

| Name | Excavator Mounted Pile Driver | Feature | Low Noise |

|---|---|---|---|

| Vibration Frequency | 3200rpm | Operation Pressure | 32Mpa |

| Hammer | 2700kg | Arm | 750kg |

| Max.Pile | 18m | Centrifugal Force | 485 Kn |

| Excavator Operating Weight | 45~60 Ton | ||

| Highlight | Low Noise Excavator Mounted Pile Driver,18 Meter Excavator Mounted Pile Driver,3200rpm Excavator Mounted Pile Driver |

||

High-Performance Pile Driver for CAT E450: 18m Depth & 3200rpm Vibro Hammer

Core Product Keywords: Hydraulic Pile Driver, CAT E450 Pile Driver, Large Excavator Pile Hammer, Deep Foundation Pile Driver, Vibratory Pile Driver, Heavy-Duty Pile Driver.

Product Overview

Designed specifically for the CAT E450 excavator platform, this heavy-duty hydraulic vibratory pile driver is engineered to tackle the most demanding deep foundation projects. With advanced European and American vibration technology integrated into a robust structural design, it delivers exceptional performance for 10–18 meter sheet pile construction while ensuring operational reliability and extended service life in challenging geological conditions.

Key Features & Technological Advantages

Proprietary Heavy-Duty Box Structure – Developed through years of industry experience, the uniquely designed box frame significantly enhances bearing durability and overall structural reliability, setting a leading standard in the piling equipment industry.

Deep Piling Capability & Adaptability – Optimized for 10–18 meter sheet pile applications with customizable eccentric group configurations and component-strength engineering, providing superior safety and performance across varied soil conditions.

High-Efficiency Vibration System – Delivers powerful centrifugal force (up to 485 KN) at high frequencies (up to 3200 RPM), ensuring fast penetration and extraction even in dense or heterogeneous ground layers.

Reinforced Heavy-Duty Components – Equipped with super-heavy cast steel fixtures, enlarged hydraulic cylinders, and reinforced connecting rods to withstand continuous high-load operation.

Premium International Core Configuration – Features high-grade German Rexroth vibration motors and imported first-tier components, ensuring stable power output, energy efficiency, and long-term operational consistency.

Technical Parameters: FV Series for CAT E450

| Model | Vibration (RPM) | Centrifugal Force (KN) | Max. Pile Length (m) | Compatible Excavator (T) | Total Weight (kg) |

|---|---|---|---|---|---|

| FV-300 | 3200 | 350 | 12 | 30–35 | 2770 |

| FV-330 | 3200 | 372 | 12 | 33–40 | 2970 |

| FV-350S | 3200 | 435 | 15 | 35–40 | 3070 |

| FV-350 | 3200 | 455 | 15 | 40–45 | 3350 |

| FV-400 | 3200 | 485 | 18 | 45–60 | 3450 |

*Note: The CAT E450 excavator typically operates within the 40–50 ton range, making models such as the FV-350 and FV-400 ideally suited for maximum depth and force performance.*

Primary Applications

Ideal for large-scale infrastructure projects including port and waterfront sheet pile walls, bridge abutments, deep foundation supports, underground parking structures, and industrial plant foundations.

Frequently Asked Questions (FAQ)

Q: Is this pile driver compatible specifically with the CAT E450 excavator?

A: Yes, it is engineered for seamless integration with the CAT E450 and other large excavators in the 40–60 ton range, with optimized hydraulic interfacing and mounting design.

Q: What ensures reliability in deep 18-meter piling applications?

A: Our proprietary box structure, combined with selectable eccentric groups and reinforced component design, provides enhanced load distribution, reduced bearing stress, and consistent performance in deep and complex geological profiles.

Q: What is the warranty coverage?

A: We offer a 12-month warranty from the installation date, covering the mainframe and key components (standard wear parts excluded).

Q: What is the minimum order quantity?

A: The minimum order quantity is one (1) set.

Q: What payment methods are accepted?

A: We accept Telegraphic Transfer (T/T).

Q: What is the typical delivery timeline?

A: Standard delivery is 7–35 days to Shanghai Port, with additional transit time required for international shipping.

Q: Can you customize the machine with our company logo?

A: Yes, we provide OEM customization including logo application upon request.

Q: How is product quality controlled?

A: All manufacturing follows strict compliance with the national "Technical Conditions for Pile Driver Enterprises" standards, supported by rigorous quality assurance throughout production.

Q: Are dealership opportunities available?

A: We welcome qualified dealers and strategic partners to collaborate as regional representatives or long-term distributors.

About YEKUN

Founded in 2014, Shanghai Yekun Machinery Co., Ltd. specializes in the research, production, and service of high-performance hydraulic vibratory pile drivers. Through continuous innovation, international technology integration, and a client-focused approach, we deliver solutions that meet the evolving demands of global infrastructure and construction sectors. Our dedicated team is committed to advancing piling technology while ensuring reliability, efficiency, and sustainability in every project.