-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

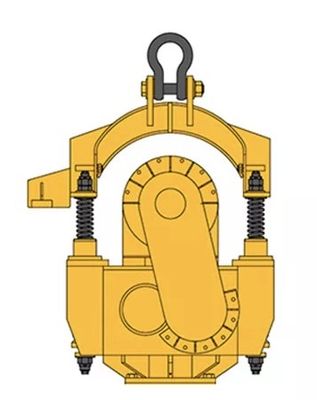

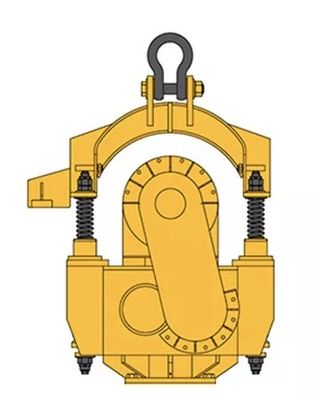

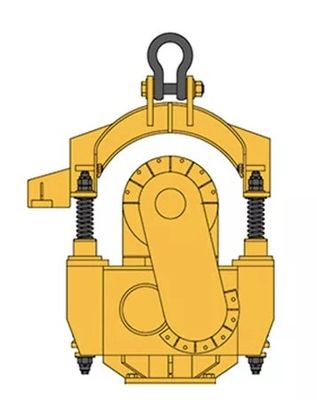

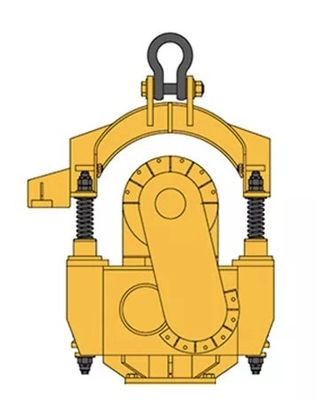

Hydraulic-Pneumatic-Electric Pile Driver - Shockproof & 2000mm Max Pile Diameter

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Pile Diameter | φ 500-1200mm, φ 500-2000mm | Total Weight | 5670 Kg |

|---|---|---|---|

| Allowable Pulling Force | 240 K N | Eccentric Moment | 460 N M |

| Motor Power | 90kw | Crawler Crane Specifications | 50 T |

| Highlight | 2000mm Electric Pile Driver,shockproof hydraulic pile driver,2000mm pneumatic Pile Driver |

||

The DZ90A Vibro Pile Driver is currently the most widely used pile foundation construction equipment in China, renowned for its reliable vertical vibration technology and versatile performance. Powered by a top domestic brand shock-resistant motor, it operates based on a scientific working principle that ensures efficient pile sinking. With strong adaptability to various construction scenarios, this pile driver is equipped with multiple fixture options and compatible with 50t crawler cranes, making it an ideal choice for large-scale foundation projects requiring stability, efficiency, and environmental compliance.

The DZ90A Vibro Pile Driver’s motor drives two groups of eccentric blocks to rotate in opposite directions. The transverse centrifugal forces generated by the blocks neutralize each other, while the vertical centrifugal forces superimpose, creating powerful vertical up-and-down vibration of the entire system to sink piles smoothly. The equipment structure consists of three core components: a shock absorber, a vibrator, and an electric system, which work together together to ensure stable and efficient operation.

- Scientific Vertical Vibration Design: Adopts dual eccentric blocks rotating in opposite directions, realizing pure vertical vibration for precise and efficient pile sinking.

- Eco-Friendly Performance: Designed for low noise and clean operation, aligning with modern environmental protection standards for construction equipment.

- Premium Core Components: Equipped with a top domestic brand shock-resistant motor and German Volkswagen heavy-duty gearbox lubricating oil.

- Flexible Fixture Options: Available with single fixture or steel pipe fixture to meet different piling requirements for various pile types.

- Broad Pile Compatibility: Supports pile diameters ranging from φ500-1200mm to φ500-2000mm, adapting to diverse project needs.

- Reliable Configuration: Compatible with 50t crawler cranes, featuring a robust structure composed of shock absorber, vibrator, and electric system.

- Comprehensive After-Sales Support: Professional after-sales engineers provide timely technical guidance and maintenance services whenever needed.

- High Efficiency & Precision: Vertical vibration technology ensures strong penetration and accurate pile placement, improving construction efficiency significantly.

- Low Maintenance Costs: German Volkswagen heavy-duty gear oil requires no replacement within one year under normal operation, reducing downtime and maintenance expenses.

- Stable & Durable Operation: The top-tier shock-resistant motor and sturdy structural design guarantee reliable performance even in harsh working environments.

- Wide Applicability: Supports various pile diameters and fixture types, making it suitable for a wide range of foundation construction projects.

- Environmental Compliance: Low-noise and clean operation minimizes impact on surrounding areas, suitable for both urban and suburban construction sites.

| Item | Specification |

|---|---|

| Motor Power | 90 kW |

| Vibration Frequency | 1050 R/MIN |

| Eccentric Moment | 460 Nm |

| Exciting Force | 570 kN |

| No-Load Amplitude | 10.3 mm |

| Allowable Pulling Force | 240 kN |

| Dimensions (Height × Length × Width) | 2.56 m × 1.53 m × 1.1 m |

| Total Weight | 5670 kg |

| Equipped Fixture | Single fixture / Steel pipe fixture |

| Pile Diameter | φ500-1200mm, φ500-2000mm |

| Generator Power | 300 kW |

| Matching Crawler Crane Specifications | 50 t |

-

Q: What is the working principle of the DZ90A pile driver?A: Its motor drives two groups of eccentric blocks to rotate oppositely; transverse centrifugal forces neutralize, while vertical forces superimpose to generate vertical vibration for pile sinking.

-

Q: Is the DZ90A pile driver environmentally friendly?A: Yes, it is designed for low noise and clean operation, complying with modern construction environmental protection standards.

-

Q: How often does the gearbox lubricating oil need to be replaced?A: It uses German Volkswagen heavy-duty gear oil, which requires no replacement within one year under normal operating conditions.

-

Q: What fixture options are available for this pile driver?A: It offers two fixture types: single fixture and steel pipe fixture, catering to different piling needs.

-

Q: What is the pile diameter range supported by the DZ90A pile driver?A: It can handle pile diameters of φ500-1200mm and φ500-2000mm, adapting to various project requirements.

-

Q: What crawler crane is compatible with this pile driver?A: It is perfectly matched with 50t crawler cranes for efficient and safe foundation construction.

-

Q: What core components make the DZ90A pile driver reliable?A: It features a top domestic brand shock-resistant motor, German gear oil, and a structure composed of shock absorber, vibrator, and electric system.

-

Q: What after-sales services are provided?A: Our professional after-sales engineers offer timely technical support, maintenance guidance, and troubleshooting services to address operational issues promptly.