-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

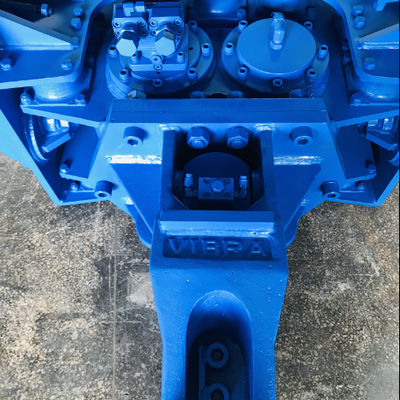

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

Pile Driver – Novel Design & Low Vibration Noise for Eco-Friendly Construction

| Name | Concrete Pile Driving Equipment | Feature | Low Vibration |

|---|---|---|---|

| Vibration Frequency | 3200rpm | Operation Pressure | 32Mpa |

| Centrifugal Force | 335KN | Max.Pile Length | 12m |

| Arm Weight | 500kg | Hammer Weight | 1900kg |

| Excavator | 20~30T | ||

| Highlight | concrete pile driver,concrete pile driving machine |

||

Pile Driver, Hydraulic Vibrating Pile Driver, High-Efficiency Pile Driver, Eco-Friendly Pile Driver, Multifunctional Pile Driver

- Efficient & Versatile Construction: Boasts fast construction speed and strong adaptability to various geological conditions, serving numerous engineering fields globally. It excels in multiple tasks such as steel sheet pile driving, vibro driven cast-in-place pile construction, and surface/deep compaction.

- Eco-Friendly Operation: Operates with low vibration and low noise, avoiding disturbance to residents and meeting environmental requirements, making it ideal for sensitive areas.

- Compact & Convenient Design: Features a novel, small-volume structure that enables easy transportation, disassembly, and assembly, enhancing on-site flexibility.

- Broad Application Scope: Widely used in municipal, water conservancy, construction, bridge, wharf, and marine engineering. Suitable for both permanent projects (e.g., dike revetments, breakwaters) and temporary projects (e.g., cofferdam construction, flood control).

- Superior Construction Quality: Adopts advanced hydraulic technology to ensure stable and reliable piling results, complying with strict industry technical standards.

- High Productivity: Fast piling speed significantly shortens project cycles and reduces overall costs.

- User-Friendly Performance: Supports free walking and steering, with simple assembly and disassembly processes that save time and labor.

- Customizable & Reliable Support: Offers LOGO customization, flexible order quantities (MOQ of 1 set), and professional after-sales service backed by a 12-month warranty.

| Item | FV-250 | FV-280 | FV-300 | FV-330 | FV-350S | FV-350 | FV-400 |

|---|---|---|---|---|---|---|---|

| Vibration Frequency (rpm) | 2500 | 2800 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Operation Pressure (Mpa) | 30 | 32 | 32 | 32 | 32 | 32 | 32 |

| Centrifugal Force (KN) | 265 | 335 | 350 | 372 | 435 | 455 | 485 |

| Max. Pile Length (m) | 10 | 12 | 12 | 12 | 15 | 15 | 18 |

| Arm Weight (kg) | 500 | 500 | 670 | 670 | 670 | 750 | 750 |

| Hammer Weight (kg) | 1700 | 1900 | 2100 | 2300 | 2400 | 2600 | 2700 |

| Excavator (T) | 20-30 | 20-30 | 30-35 | 33-40 | 35-40 | 40-45 | 45-60 |

Shanghai Yekun Construction Machinery Co., Ltd., established in 2014, is a professional enterprise specializing in the manufacture, sale, and service of hydraulic vibrating pile drivers. We focus on high-speed hydraulic vibrating pile drivers and their components, catering to the infrastructure and construction industries. With cutting-edge technology, a young and passionate professional team, and a commitment to "Client Priority, Quality First, Management Foundation", we have gained high recognition for our mini, medium, and large-sized pile drivers. We collaborate with engineering machinery factories and construction companies for product development and employ foreign professionals as technical advisors, striving to become the most professional and comprehensive pile driver supplier.

A: The warranty period is 12 months from the completion of installation, covering the mainframe and key components (excluding wearing parts).

A: One set is acceptable.

A: We support L/C, T/T, and D/P payment methods.

A: The general delivery time is 1-8 days, with delivery to Shanghai Port. Overseas orders require additional consideration of shipping time.

A: Yes, LOGO customization is available.

A: Our equipment is strictly manufactured in accordance with the technical standards outlined in "Technical Conditions for Pile Driver Enterprises".

A: We warmly welcome you to become our dealer and look forward to developing long-term cooperation as regional general agents and strategic partners with ambitious individuals like you!