-

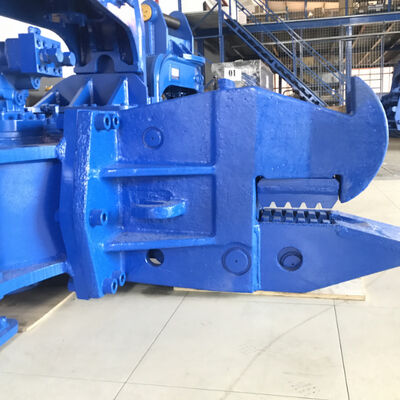

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

High Piling Speed Pile Driver - Low Noise Hydraulic System & Universal Fit

| Name | Hydraulic Pile Driver | Operation Pressure | 32Mpa |

|---|---|---|---|

| Arm Weight | 750kg | Hammer Weight | 2700kg |

| Vibration Frequency | 3200rpm | Condition | New |

| Centrifugal Force | 485 Kn | Excavator | 45~60 Ton |

| Highlight | hydraulic pile driving machine,hydraulic pile driving equipment |

||

Pile Driver, Low Noise Hydraulic Pile Driver, Multi-Pile Compatible Pile Driver, Universal Excavator Pile Driver, Quick Conversion Pile Driver, Low Vibration Pile Driver, Damage-Free Pile Driver, Versatile Working Environment Pile Driver

Shanghai Yekun’s Low Noise Hydraulic Pile Driver is a professional construction solution engineered for versatility across diverse working environments. Integrating low noise, high efficiency, and user-centric design, it excels in piling, pile pulling, and multi-task operations while protecting piles and surrounding structures. Equipped with advanced hydraulic technology and flexible operational features, it meets the demands of infrastructure and construction projects with reliable performance and environmental compliance.

- Multi-Pile Compatibility: Efficiently drives steel sheet piles, cement piles, steel rail piles, iron plates, and H-steel; requires less force for pile pulling compared to conventional systems.

- Low Noise & Vibration: Adopts rubber sheath technology to reduce noise and vibration, ensuring quiet operation and solving environmental problems, even when working near buildings.

- Pile & Structure Protection: Avoids damage to the top/bottom of steel pipe piles, steel plate piles, and steel rail piles; protects adjacent buildings during close-proximity operations.

- Operational Flexibility: 180° forward/reverse rotation for clamping/lowering sheet piles (adapts to pile placement and site conditions); 2-level vibration frequency adjustment + dual-pump combination to enhance excitation force.

- Universal Excavator Fit: Compatible with any brand of excavator; meets different work requirements by simply replacing chucks, no specialized equipment needed.

- Advanced Hydraulic System: Variable pump enables flexible vibration frequency adjustment; compact, lightweight hydraulic motor delivers high power and speed.

- Quick Conversion & Efficiency: Fast operation switching shortens working periods, boosting productivity across various construction scenarios.

-

Environmental Compliance: Low noise and vibration design complies with environmental standards, making it suitable for noise-sensitive areas (residential zones, urban construction sites).

-

Broad Adaptability: Applies to various working environments and multiple pile types, eliminating the need for specialized equipment and reducing project costs.

-

Universal Compatibility: Works with 20–60T excavators of any brand, maximizing utilization of existing construction fleets and enhancing operational flexibility.

-

Cost-Saving Performance: Damage-free operation reduces repair/replacement costs; quick conversion and low-force pile pulling save time and labor.

-

User-Friendly Operation: Intuitive design, adjustable vibration frequency, and 180° rotational function adapt to complex site conditions, lowering operator fatigue.

-

Reliable Quality: Manufactured in strict accordance with "Technical Conditions for Pile Driver Enterprises" and equipped with advanced industrial technology, ensuring long-term stable performance.

-

High Power-to-Weight Ratio: Compact hydraulic motor delivers high power and speed, balancing performance and portability for easy transportation and deployment.

| Item | FV-250 | FV-280 | FV-300 | FV-330 | FV-350S | FV-350 | FV-400 |

|---|---|---|---|---|---|---|---|

| Vibration Frequency (rpm) | 2500 | 2800 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Operation Pressure (Mpa) | 30 | 32 | 32 | 32 | 32 | 32 | 32 |

| Centrifugal Force (KN) | 265 | 335 | 350 | 372 | 435 | 455 | 485 |

| Max. Pile Length (m) | 10 | 12 | 12 | 12 | 15 | 15 | 18 |

| Arm Weight (kg) | 500 | 500 | 670 | 670 | 670 | 750 | 750 |

| Hammer Weight (kg) | 1700 | 1900 | 2100 | 2300 | 2400 | 2600 | 2700 |

| Compatible Excavator (T) | 20-30 | 20-30 | 30-35 | 33-40 | 35-40 | 40-45 | 45-60 |

-

Q: What is the warranty period for this Pile Driver?

A: The warranty period is 12 months from the date of installation completion, covering the mainframe and key components (excluding wearing parts).

-

Q: What is the minimum order quantity (MOQ)?

A: One set is available for purchase.

-

Q: Which payment methods do you accept?

A: We accept T/T, and D/P payment terms.

-

Q: What is the delivery time?

A: The delivery time is generally 7–35 days, with goods delivered to Shanghai Port. Overseas shipping time is additional.

-

Q: Can I customize the machine with our LOGO?

A: Yes, custom LOGO printing on the machine is available.

-

Q: How is the product quality guaranteed?

A: Our equipment is strictly manufactured in accordance with the technical standards specified in "Technical Conditions for Pile Driver Enterprises".

-

Q: Can I become your dealer?

A: We welcome applications to become our dealer and look forward to developing long-term partnerships as regional general agents or strategic partners.

Shanghai Yekun Construction Machinery Co., Ltd., founded in 2014, is a professional enterprise specializing in the manufacture, sale, and service of hydraulic vibrating pile drivers. Our core products include high-speed hydraulic vibrating pile drivers and their components, which are widely applied in infrastructure and construction industries.

We prioritize product quality by adopting the latest industrial technology. Our mini hydraulic vibrating pile drivers lead the industry trend, while medium and large models are highly recognized by clients. We actively cooperate with engineering machinery factories and construction companies to develop more functional professional equipment, and we hire foreign professionals as technical advisors.

Composed of a young, passionate, and professional team, we adhere to the principles of "Client First, Quality as Priority, Management as Foundation". Our goal is to become the most professional and comprehensive hydraulic vibrating pile driver manufacturer and service provider in the industry.