-

Hydraulic Pile Driver

-

Excavator Mounted Pile Driver

-

Electric Vibratory Hammer

-

Side Grip Pile Driver

-

Four Eccentric Pile Driver

-

360 Degree Pile Driver

-

Mini Excavator Pile Driver

-

Concrete Pile Driving Equipment

-

Pile Driver Long Boom

-

Mechanical Boom

-

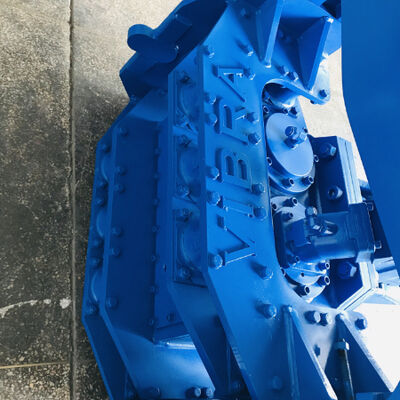

Pile Driver Parts

-

Bore Drilling Machine

-

Hydraulic Hedge Cutter

-

Hydraulic Trencher

-

Photovoltaic Pile Driver

-

Sheet Pile Driving Machine

-

Hydraulic Impact Hammer

-

Hydraulic Pile Breaker

High-Visibility Yellow Pile Driver | Enhanced Safety & Multi-Functional Performance

| Name | Hydraulic Sheet Pile Driver | Feature | Yellow Color |

|---|---|---|---|

| Vibration Frequency | 3200rpm | Operation Pressure | 32Mpa |

| Arm Weight | 500kg | Hammer Weight | 1900kg |

| Centrifugal Force | 335KN | Excavator | 20-30T |

| Max Pile Length | 12m | ||

| Highlight | sheet pile driving equipment,sheet pile installation machine |

||

High-Visibility Yellow Pile Driver | Enhanced Safety & Multi-Functional Performance

Product Keywords: High-Capacity Pile Driver, Side Piling Machine, Corner Piling Machine, Hydraulic Pile Driver, Multi-Shape Pile Driver, Vibratory Pile Hammer, Concrete Pile Driver

The YEKUN High-Capacity Hydraulic Vibratory Pile Driver sets a new industry standard with its exceptional capability in side piling and corner piling applications, outperforming competitors in operational range and flexibility. Engineered for ultimate versatility, it seamlessly works with a vast variety of piles—including square, round, and other shaped steel piles—as well as both thin-walled and thick-walled concrete piles, making it the ideal solution for complex foundation projects.

- Superior Side & Corner Piling: Engineered with a larger capacity for challenging side and corner piling tasks, offering greater versatility than standard machines.

- Unmatched Pile Compatibility: Handles an extensive range of pile types and shapes: steel sheet piles, cement piles, steel rail piles, iron plates, H-beams, and both thin- and thick-walled concrete piles of various geometries.

- Quick-Change Operation: Enables rapid conversion between driving and extracting functions, adapting efficiently to diverse site conditions.

- Advanced Noise/Vibration Dampening: Integrated rubber sheath technology drastically reduces operational noise and vibration for quieter, shorter work cycles in sensitive environments.

- Precision Clamping & Adjustable Power: Features a 180° rotatable clamp for exact positioning. A two-level adjustable vibration frequency, combined with a dual-pump system, delivers superior excitation force.

- Compact, High-Power Drive: A lightweight, small-volume hydraulic motor provides high power and speed output for maximum efficiency.

- Universal Excavator Compatibility: Mounts on any excavator brand. Simple chuck changes allow adaptation to specific pile types and job requirements.

- Efficient & Non-Destructive: Designed to extract piles with less force and to operate without damaging pile ends or adjacent structures.

- Unrivaled Application Range: Excels in demanding side and corner piling scenarios while handling an unmatched variety of pile materials and shapes, eliminating the need for multiple specialized machines.

- Enhanced Project Flexibility & Efficiency: Its superior capacity and quick-change functionality enable faster completion of complex piling layouts, reducing overall project timelines.

- Site-Friendly Operation: Low-noise, low-vibration design minimizes environmental impact and allows work in restricted or urban areas.

- Cost-Effective Solution: One machine for multiple applications reduces capital expenditure, rental costs, and on-site equipment footprint.

- Reliable & Protective Performance: Robust construction ensures durability and reliable operation while safeguarding pile integrity and nearby buildings.

| Model | FV-250 | FV-280 | FV-300 | FV-330 | FV-350S | FV-350 | FV-400 |

|---|---|---|---|---|---|---|---|

| Vibration Frequency (rpm) | 2500 | 2800 | 3200 | 3200 | 3200 | 3200 | 3200 |

| Centrifugal Force (KN) | 265 | 335 | 350 | 372 | 435 | 455 | 485 |

| Max. Pile Length (m) | 10 | 12 | 12 | 12 | 15 | 15 | 18 |

| Hammer Weight (kg) | 1700 | 1900 | 2100 | 2300 | 2400 | 2600 | 2700 |

| Compatible Excavator (T) | 20-30 | 20-30 | 30-35 | 33-40 | 35-40 | 40-45 | 45-60 |

Founded in 2014, Shanghai YEKUN Machinery Co., Ltd. is a dedicated specialist in the design and manufacture of high-performance hydraulic vibratory pile drivers. We focus on integrating advanced technology to create powerful, versatile, and reliable equipment for the global infrastructure sector. Our commitment to innovation, supported by a skilled team and international technical expertise, drives us to deliver solutions that meet the evolving challenges of modern construction.

- Q: What makes your pile driver better for side and corner piling?

A: Our machines are specifically engineered with a larger operational capacity and optimized geometry, providing greater reach, stability, and force application in challenging side and corner piling situations compared to standard models. - Q: Can it really handle both thin-walled and thick-walled concrete piles?

A: Yes, absolutely. The adjustable vibration frequency and controlled excitation force allow it to efficiently drive and extract concrete piles regardless of wall thickness, from thin-walled to heavy thick-walled designs. - Q: What is the warranty period?

A: We provide a 12-month warranty for the main host and key components from the installation completion date (standard wear parts are excluded). - Q: What is the minimum order quantity?

A: The MOQ is one set. - Q: What payment methods are accepted?

A: We accept T/T. - Q: What is the delivery lead time?

A: Standard delivery is 7-35 days to Shanghai Port, with additional shipping time required for overseas destinations. - Q: Can you provide technical support for specific piling projects?

A: Yes, our technical team can provide application support and recommendations based on your specific project requirements, pile types, and soil conditions.